Description

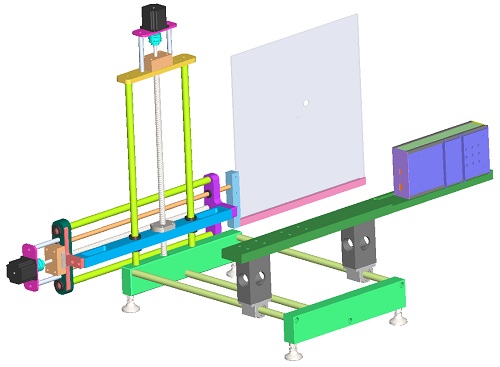

To provide time-varying patterns of attenuating material for time-encoded imaging, we built a programmable mask positioning system. The so-called “Mira” system also enables repeatable placement of a single Polaris SP plane on a stage facing the mask and can align the cathodes of the array between about 12 cm and 60 cm from mask plane.

The Mira system is pictured in Figure 1 with a single plane of Polaris SP. Most components are made of Al, except (most notably) the vertical and horizontal ball screws and vertical support rods that are made of steel. The ball screws are each connected to a stepper motor that is wired to a driver and controlled using an Arduino Uno board.

Figure1. Angled view of Mira and Polaris SP

Figure 2. Block diagram for a time-encoded measurement using Mira and Polaris

The two degrees of freedom offered by the perpendicular ball screws allow for x; y positioning of a coded aperture mask within a 17 in 17 in the area, the extent of the ball screw range. The range ends are monitored by limit switches that inform the Arduino that the mask is traveling out range when contact is made. A simple block diagram of the setup is provided in Figure 2.

Arduino code for detection of muscle fatigue and muscle growth

Reviews

There are no reviews yet.