introduction

The planning, development and implementation of a sprawling urban city is no easy task. For a moment, consider the modern metropolitan city perhaps in which you may currently reside; at some point, a city planner considered the effects of each additional roadway, neighborhood, shopping plaza or educational campus. The coordination of traffic, whether it be commercial, residential or pedestrian must be painstakingly reviewed and analyzed for efficiency and efficacy. A city planner must debate the location of potential city parks and recreational areas along with the types of plants that reside there. Minute details such as the fabric used on decorative lampposts, or the bulbs used in said lamps, must all be considered as they all have a potential impact on the city and its sustainability. Energy conservation strategies, such as day lighting, shade for natural cooling or wind patterns that may impact each building’s envelope are all elements that must be deliberated. Erosion and storm water maintenance can be impacted by proper landscaping, natural vegetation, and irrigation must be considered. Although many residents will pass by these objects without much thought, every element of a developing sustainable city has a purpose and an impact. The same consideration must be applied to the materials that are used in its establishment; especially with regards to its major power and IT networks. This paper takes aim at the potential environmental impacts of materials utilized by the telecommunication industry during the expansion of the geographical network footprint in an expanding city.

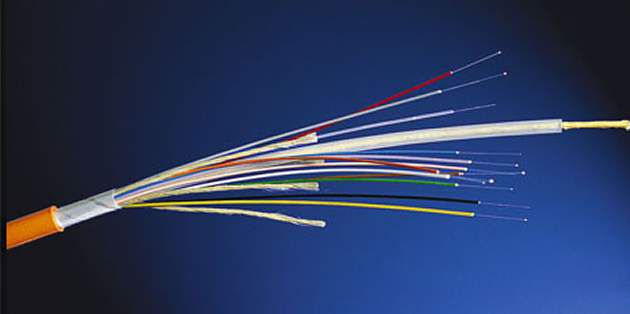

Figure 1: Shielded twisted pair cable

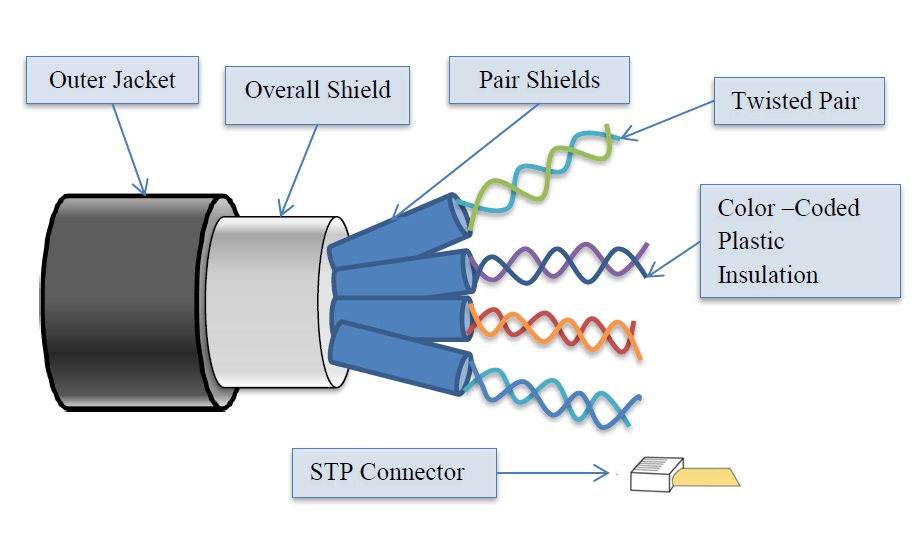

Fiber optic cable is unlike any other cable used in the industry. First and foremost, fiber optic cable does not transmit signal through pulses of electricity. Originally developed by Alexander Graham Bell, with the introduction of his Photo phone, optical transmission was thought of as a revolutionary technology. At the time, wire was the established method to transfer information due to its reliability; Bell wished to improve on this by transmitting through air, thus altering his research to focus on light as a means of communication . Fiber optic cable transfers information through pulses of light through a translucent yet reflective material such as glass. Today’s modern fiber optic cables are comprised of glass fibers bundled together to transmit signal at, or near, the speed of light, faster than any other cable developed today. In just the past 3 years, researchers have been able to obtain speeds of over 100 Terabytes of information per second on the most advanced Fiber Optic Cabling. Figure 3 below demonstrates in a fairly simple way, how the multiple signals can be passed along one single strand of fiber optic glass, allowing for greater transmission loads.

Figure 3: Fiber optic cable signal

Telecommunication companies invest a considerable amount of their budget on continually upgrading their network’s footprint, which is the actual interconnected cable infrastructure that allows access to the internet. These companies consume a substantial amount of cabling each day, expanding their grid in order to service more clients. Although, each form of cable offers potential benefits, both economically and through increased reliability, it has become apparent that little research has been conducted on the overall sustainability of network cabling especially with regards to the potential environmental effects of its production, consumption, and disposal. Coaxial cables, for example, are comprised of aluminum, chromium, cadmium, mercury, beryllium, nickel, zinc and copper; some of which are considered quite detrimental to the environment. In fact, studies show that these metals make up over 5% of municipal waste. Furthermore, taking into account the massive scale of a thriving telecom network, the thermoplastic compound applied to the exterior of the cable places a considerable strain on the environment. Although the production of fiber optic cabling is fairly commoditized, each company holds their plastic mixture as proprietary information. In order to address this, the research detailed in this paper surrounded the most common plastics found in fiber optic cables, substantiated by experts at a large fiber optic manufacturer. The plastics delineated as the most common and making up the bulk of the proprietary mixture are Polyethylene Terephthalate (PET), High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC).