Basics of screws

The screw, a simple machine, is an inclined plane wrapped around a cylinder, used either as a fastener or as a force and motion modifier. Screws take many forms; the most common form consists of a cylindrical shaft with helical grooves or ridges called threads on the external surface. The screw acts as a mechanism that converts rotational motion to linear motion, and a torque (rotational force) to a linear force.

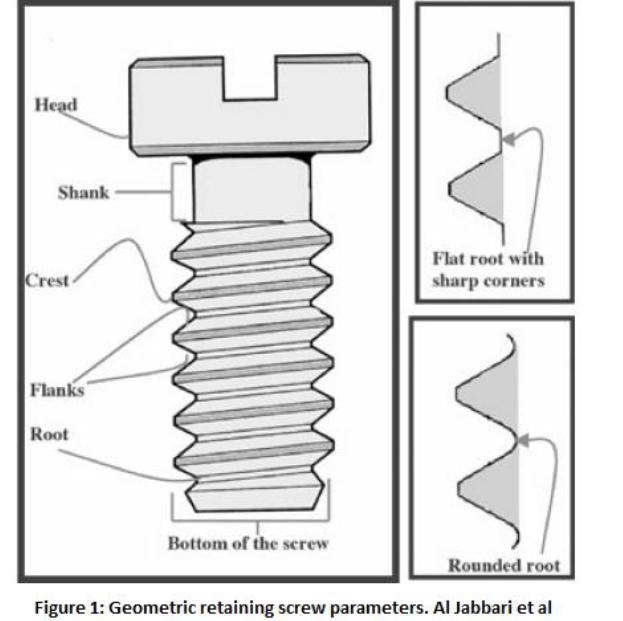

figure 1

Many attempts have been made to standardize screw types and designs. The International Association for Standardization standard is one of the most common standardizations existing for screw threads. Another system for standardization, the Unified Thread Standard (UTS), commonly used in the United States, is a non metric inch-sized thread type standardization. Both systems share the same thread geometry but not the absolute dimensions. Both use similar parameters to describe screws. The shaft of the screw has two diameters: Major and minor. The major diameter is measured between the crests of the threads. The minor diameter is measured between the roots of the threads (Fig. 1 and Fig. 2).

Other parameters

include the lead and the pitch. The lead is the linear distance the screw travels axially in one complete revolution (360°) of the shaft. The pitch is the axial distance between the crests of adjacent threads measured parallel to the axis. Coarse threads are those with larger pitch and fine threads are those with smaller pitch. An additional category in includes extra fine, with a very fine pitch thread. Extra fine pitch metric threads are more resistant to becoming loose from vibration . The lead and the pitch determine the mechanical advantage of the screw; the smaller the lead and/or pitch, the higher the mechanical advantage .Many attempts have been made to standardize screw types and designs. The International Association for Standardization standard is one of the most common standardizations existing for screw threads. Another system for standardization, the Unified Thread Standard (UTS), commonly used in the United States, is a non metric inch-sized thread type standardization. Both systems share the same thread geometry but not the absolute dimensions. Both use similar parameters to describe screws. The shaft of the screw has two diameters: Major and minor. The major diameter is measured between the crests of the threads. The minor diameter is measured between the roots of the threads (Fig. 1 and Fig. 2). Other parameters include the lead and the pitch. The lead is the linear distance the screw travels axially in one complete revolution (360°) of the shaft. The pitch is the axial distance between the crests of adjacent threads measured parallel to the axis. Coarse threads are those with larger pitch and fine threads are those with smaller pitch. An additional category in includes extra fine, with a very fine pitch thread. Extra fine pitch metric threads are more resistant to becoming loose from vibration . The lead and the pitch determine the mechanical advantage of the screw; the smaller the lead and/or pitch, the higher the mechanical advantage.

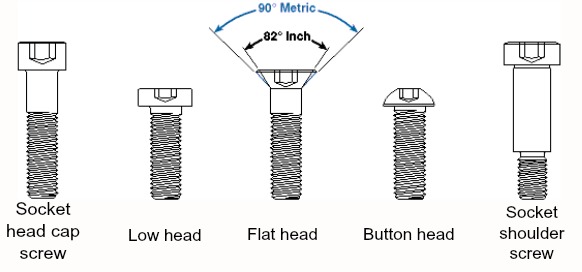

figure 2

The helix of a screw’s thread can turn in two possible directions. This is known as handedness. Most screws are right-handed; the screw is tightened when turned in a clockwise direction. The root of the threads can be rounded or flat (Fig. 1). The thread angle of a screw is the angle between the threads. Both ISO and UTS screws have V thread design. Other designs in other standardizations include: Whitworth threads, Pipe thread, Acme thread, Buttress and Square .