Overview of Industrial Control Systems

Industrial Control Systems

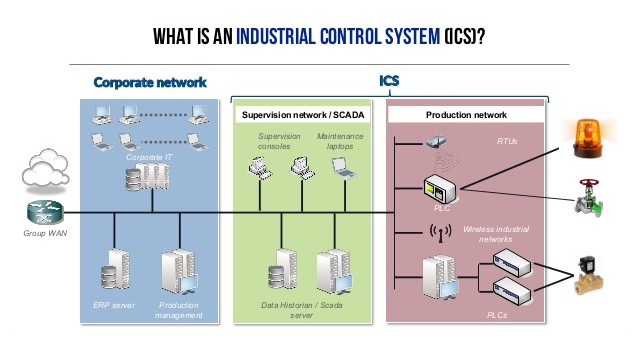

The term industrial control system (ICS) encompasses numerous types of control systems, such as distributed control systems (DCS), supervisory control and data acquisition (SCADA) systems, as well as programmable logic controllers (PLC) which are usually found in critical infrastructure systems and the industrial sector. An ICS is comprised of combinations of different electrical, mechanical, hydraulic, and pneumatic control components which can be are integrated together in order to achieve an industry specific task in the manufacturing, transportation or energy sectors. The aspect of the system primarily concerned with producing the output is referred to as the process while the control portion of the system consist of the specifications required to obtain the desired output or performance. The process control loop may include human intervention or be fully automated . Typical control systems can be configured to operate in manual mode, open-loop or closedloop. In open-loop control systems the output is controlled by established settings. In closed-loop control systems, the process output provides feedback which is essential to adjusting the process to achieve the desired objective or set point. A system operated in manual mode requires human intervention and is completely controlled by human input. The aspect of a control system dedicated to maintaining conformance within specified operating parameters is referred to as the controller. Typical ICS may contain several different control loops, graphical interfaces called Human Machine Interfaces (HMIs), as well as remote diagnostic maintenance tools built using an assortment of network protocols for advanced troubleshooting. ICS are used to monitor and control processes in various industries such as electrical power generation, transmission and distribution, oil and natural gas refining, pulp and paper, water and wastewater processing, discrete manufacturing (e.g., aerospace, automotive, food and beverage, chemical, pharmaceutical) and transportation industries . ICS are also critical to the successfully operating critical infrastructure in the United States. The U.S. has a highly sophisticated and interconnected systems that are mutually dependent. It is noteworthy that approximately 85% of critical U.S. infrastructure is privately owned and operated1. Numerous other industries previously mentioned above are operated by Federal agencies including air traffic control. Modern ICSs have evolved significantly due to the integration of Information and Communications Technology (ICT) to replace and supplement physical mechanisms. Mechanical controls used in engines and rotating machines that were previously analog have been replaced with embedded digital controls. The result of ICT integration is improved equipment performance and reduced cost of operation. The smart use of new technologies have evolved into “smart systems” such as smart buildings, smart manufacturing, smart transportation, and a smart electric power grid. The interconnectivity of these critical systems requires a corresponding requirement for greater resilience, adaptability, safety and high levels of security. The engineering of ICS must continuously evolve with new models and analysis to address the emerging security implications and threats to public safety due to the introduction of IT technologies and the complex interdependencies of critical systems .A wide variety of industrial sectors namely distribution, manufacturing and transportation require the use of control systems. The manufacturing industry is a highly diverse and enormous industry with several processes. These processes can typically fall into two categories and are described as either discrete-based or processed-based manufacturing. Discrete manufacturing industries utilize a series of steps on an individual device to create a final product. Examples of discrete manufacturing industries are Parts machining and Mechanical parts assembly. Process-based manufacturing uses two primary processes called Batch manufacturing and Continuous manufacturing . Batch manufacturing processes such as in food manufacturing involve specific steps carried out on a quantity of material. The batch process has a specific start and stop and can potentially include a period of steady state operations when there are intermediate steps. Continuous manufacturing processes such as chemical distillation or steam flow in a power plant are carried out continuously with transitions used to produce different grades of a product. Both discrete and process based industries use similar sensors and networks in their control systems while particular facilities require a hybrid of discrete and process-driven manufacturing. The Distribution Industries consist of assets that are geographically dispersed and are separated by thousands of kilometers such as oil and natural gas pipelines, railway transportation systems, water distribution & wastewater collection systems along with electrical power grids. While there may be similarities between control systems used in the manufacturing and distribution industries, there are some key differences. One difference is that manufacturing industries are physically restricted to a plant or factory space while distribution industries have physical locations that are geographically dispersed. The communication requirements in manufacturing industries are usually satisfied by a reliable high speed local area network (LAN). The long-distance communication needs required by distribution systems are met by wireless/radio frequency (RF) and wide-area networks (WAN) technologies. The ICS used for distribution systems are designed to handle data loss, delays and security controls across different networks and communication media . The U.S. has often been described as a “system of systems” due to the high interdependency between industrial sectors and private sector business partners. Critical infrastructure are interconnected physically and via ICT systems. An incident occurring in one infrastructure can potentially affect other infrastructures directly or indirectly by causing escalating and cascading failures. The electric power transmission and distribution industries both utilize SCADA systems that are geographically distributed to operate systems that are highly integrated and dynamic. These systems are comprised of thousands of private and public utilities as well as rural cooperatives to supply end users with electricity. Centralized SCADA systems are used to control and monitor the distribution of electricity by issuing commands and collecting data from remote field control stations that are geographically dispersed. Other industries such as oil and natural gas distribution, pipelines, water distribution & waste water collection systems, railway, trucks and ships are all monitored and controlled from SCADA systems. SCADA systems are often networked with Distributed Control Systems (DCS) particularly in the power industry. Electrical power generation facilities and control centers are typically controlled by a DCS which are then networked with SCADA systems in order to coordinate production output based on demands for power transmission and distribution. The electrical power industry is one of the predominant sources of disruption to critical interdependent infrastructures. A major disruption in the communications network of a SCADA system for an electrical power transmission facility can potentially trigger a cascading failure. The potential loss of control and monitoring functionality could result in a major generation unit being taken offline hence a loss power at an electrical transmission substation. The offline unit would cause a major imbalance of load and generation that could trigger blackouts in large areas including loss of power to other production facilities such as water treatment & waste water collection systems, refinery operations, as well as oil and natural gas production which all rely on reliable electric power from the grid .